A landslip may have been the catalyst for the Stonehaven rail crash, but it would be a mistake to assume this is an open-and-shut case.

As part of the official inquiry, investigators will be examining all sorts of unseen elements which are usually considered to be run-of-the-mill.

From how old the train was to how steep the slopes surrounding the track are, there are a great number of variables that each contributed to the event which unfolded on August 12.

Earthworks

To most people, the term “earthworks” probably doesn’t mean much. But this hidden component of British railways is just as important as the tracks and trains in keeping the network running.

Earthworks refer to a variety of engineering techniques designed to allow trains to pass over difficult terrain and steep hills. In most cases, this means adding or removing soil to create a flat surface.

There are three main categories of earthworks:

- Embankments: Adding soil to level off the ground and allow railway lines to pass at an acceptable level.

- Soil cuttings: An excavation that removes ground predominantly composed of soil to allow railway lines to pass on a level surface.

- Rock cuttings: Similar to the above, this involves an excavation that removes ground predominantly composed of solid rock to allow railway lines to pass on a level surface.

Network Rail manages a portfolio of some 190,000 earthworks, most of which were built 150 years ago.

While on the one hand this has been hailed as a great feat of engineering from the Victorian navvies of the day, on the other, it presents some real difficulties when it comes to modern-day standards.

The legacy of overly steep embankments and near-vertical rock faces which exist today is a direct result of the limited construction methods available at the time to the Victorians (along with a distinct lack of health and safety requirements).

It’s impossible to compare this historic construction with the resilience and capabilities of modern engineered slopes. It also means that upgrading almost the entire rail network would be a mammoth task.

So it all comes down to risk. Network Rail has assessed each metre of track and rated each earthwork according to its level of risk and thus potential for failure.

The bigger the hazard, the higher up the site will appear on the “to-do” list, enabling Network Rail to prioritise their repairs.

When assessing how vulnerable an earthworks asset is, there is one critical factor to consider: Water.

According to Network Rail, the stability and resilience of earthworks is, in most cases, entirely dependent on the control of water around it.

It is easy to see why this is the case. Vulnerabilities in railway infrastructure are almost always exposed following storms or prolonged periods of wet weather.

But once again, upgrading drainage systems to cope with increasingly extreme weather events is a very costly business, and each year upwards of £25 million is spent on strengthening earthworks against water damage.

In June, 2018 Network Rail published an earthworks technical strategy plan which, among other things, detailed some of the ways they are working to improve water management on the railways.

Perhaps one of the key points in the strategy is the new plan to both “identify and fix the root cause” of drainage issues, rather than just treating the symptom.

In the past, drainage works have focused almost exclusively on diverting water from the tracks, using drainage pits, pumps and barriers to redirect flood waters.

And as lines are renewed in flood-prone areas, tracks and signalling equipment have been reinstalled at a higher level so it’s less likely they’ll be flooded.

But moving forward it is clear that, while the railways are only getting older, our weather is only going to get more extreme.

In what has become a matter of urgency, Network Rail says it is investing increasing amounts of cash to improve its weather resilience.

In the five years up to the end of 2024, the organisation is aiming to invest £1.274 billion solely on the maintenance and renewal of earthworks and drainage.

This marks an increase of 20% on the previous five years (2014-2019) and is nearly double the spending of the five years before that.

Clearly the need to address our changing weather is becoming more pressing, as old age and increased rainfall take their toll on our historic railways.

Bridges

From the impressive feet of engineering which is the Forth Rail Bridge to the tiny stone crossings in the middle of quiet countryside, bridges of all shapes and sizes are a necessity when traveling by train.

Just like the train tracks themselves, many of the bridges and viaducts in use today date back from the Victorian era, and it seems that being responsible for these examples of national heritage is both a privilege and a challenge for their owners.

In Scotland, the vast bulk – approximately 5,000 bridges – are owned and maintained by Network Rail.

Each year thousands of man-hours are spent carefully strengthening and replacing old bridges to bring them in line with modern safety requirements and to protect them from extreme weather.

The costs for this easily run into the tens of millions of pounds.

Each bridge is inspected annually for wear and tear and more detailed inspections take place every three-to-five years for long-term issues.

Bridges considered to be higher risk – usually ones that are particularly old or have stonework below water – are reviewed even more regularly.

Every bridge or viaduct in Scotland is unique

One of the difficulties in standardising ongoing bridge maintenance is almost every bridge or viaduct in Scotland is unique, except for the most modern structures which are now being built to clear-cut specifications.

Historically each bridge was built to fit exactly into its surrounding landscape with whatever materials were available, so structures varied wildly across the country.

Another reason for the huge diversity in bridges across Scotland can be traced back to when each of the railway routes were being constructed.

There was huge competition for business and countless different firms were awarded contracts to construct railways all over the country.

For example the firm which built the Glasgow-to-Dumfries line was different to the firm which completed the Dundee-to-Aberdeen route, and each company had different materials and design ideas at their disposal.

These inconsistencies in bridge building can be seen across Scotland, and it wasn’t until the 20th century that the railways became more streamlined in their building methods.

As a result of the varied style of bridge, each one is repaired on a case-by-case basis: What works for the steel cantilever Forth Rail Bridge is unlikely to be suitable for the traditional stonemasonry of a Victorian viaduct.

Another aspect to consider is bridge positioning. Bridges that cross large, open bodies of water are generally far more exposed to the elements than those inland, and therefore require more upkeep.

Meanwhile crossings in remote parts of the Highlands must be hardy enough to endure regular sub-zero temperatures, and can become all but inaccessible in difficult winter weather conditions.

These variations require each bridge or viaduct to be specifically designed to withstand different challenges. So there is no one-size-fits-all approach when it comes to maintenance.

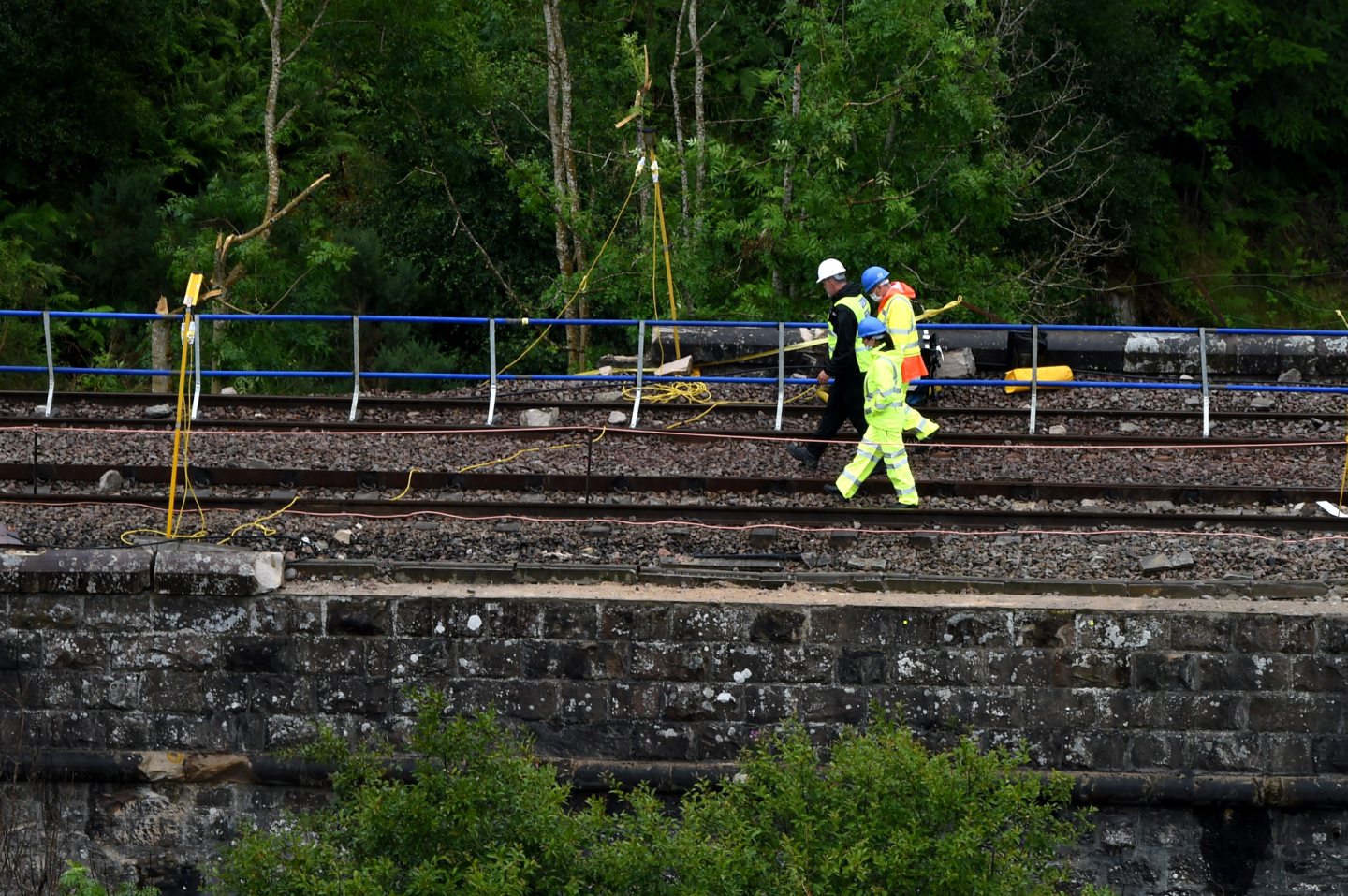

Making repairs at Carmont

In a strange coincidence, the bridge at Carmont – where the train fatally derailed on August 12 – happened to be undergoing exactly this sort of specific maintenance at the time of the crash.

It had been identified some years earlier as one of several bridges situated in fast-flowing rivers around Scotland where foundations weren’t as deep as they could be.

The catalyst for this strengthening of foundations was the collapse of the Lamington Viaduct on the West Coast Mainline in 2015, which almost washed away due to heavy flooding after the foundations failed.

Though nothing had gone wrong at Carmont, Network Rail wanted to make alterations before anything did, so in the summer of 2019 submitted a proposed plan to strengthen the bridge’s single-span (one-arch) foundations.

The exact location of the bridge made it a trickier fix than usual, and with no direct access down to the water, workmen created a makeshift road out of ramps to cross bracken fields and gain access to the site.

By the morning of August 12, there was a team on the ground making preparations to begin work.

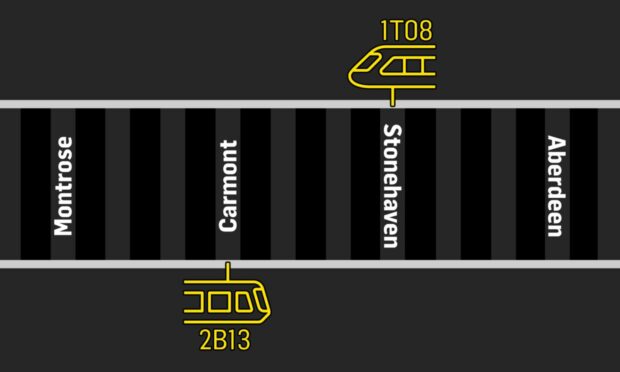

At approximately 9.38am, they found a horrifying scene unfolding just meters away as the four-carriage InterCity service, now bound for Stonehaven, seemed to burst out of nowhere and strike one of the bridge parapets.

It had hit a landslip just moments earlier, which derailed the leading car. And as the track curved to the right approaching the bridge, the train – no longer on its tracks – had continued straight.

The parapet was instantly destroyed and the leading power car fell down the wooded embankment and caught fire.

In a matter of seconds the first carriage turned sideways, and came to rest across the tracks, overturned, along with the second carriage, also overturned, and the fourth, lying on top of it along with the rear power car.

Meanwhile the third carriage ended up lying on its side mid-way down the embankment.

Standing just out of danger, the bridge repair workers watched on in horror as they made calls to the emergency services to alert them to the seemingly freak accident.

It was later discovered that the initial landslip had been caused by the failure of a drain which Network Rail had installed in 2010 and had last been inspected in June 2020, though no faults had been found.

Yet it was the location and make-up of the bridge which appears to have proved most disastrous.

At the time of the crash, the driver had been instructed to drive at 72.8mph. The speed limit on that section of line was 75mph.

The combination of the speed of the train, and the fact that it came around a bend at the scene of the derailment, gave the driver, Brett McCullough, almost no time to react. Experts say he behaved with utmost professional.

The train may have stayed upright had the route and track been straight.

However, hindsight is a wonderful thing, and it is easy to speculate about what may or may not have happened under different circumstances.

Meanwhile the crash is currently being investigated by multiple agencies as expected, and two major reports on the incident are set to be released in 2021.

A point investigators may put forward for consideration is whether Network Rail should consider making all bridge approaches straight in light of this incident. Or, in the same vein, introducing speed limits when approaching curved tracks on bridges.

However, rail experts have told us the cost of this would be prohibitive as there are so many curved bridges on the UK rail network.

Either way, the scope of the ongoing investigations is set to be extremely thorough and it is likely to be some six months at least before the findings are revealed.